Motorized Butterfly Valve – Extended Shaft / Decanter Valves

Motorized Butterfly Valve – Extended Shaft / Decanter Valves with electrical actuator are used in underwater controls. This type of extended valves are required when the valve needs to be setup in places where the pipeline is immersed in the sump. With the extended shaft the electrical portions of the actuator are above the tank or ground level. Our Electric actuators can be easily mounted on top of the Butterfly Valve using ISO 5211 standard pads. They are available in ON/OFF and Modulating versions.

Extended Shaft for Remote and Safe Actuation

The most prominent feature of the motorized butterfly valve in decanter applications is the extended shaft. This extension allows the electric actuator to be installed at a remote location, typically several feet above the valve body. In many installations, the valve sits at the bottom of tanks or sumps where space is limited or access is hazardous. The extended shaft brings the actuator to an accessible and safe location, allowing operators to control the valve without entering confined or submerged areas.

Thermal Isolation in High-Temperature Environments

In applications where the fluid is hot or the valve is installed near heat sources, the extended shaft plays a crucial role in thermal isolation. It physically separates the actuator from the high-temperature zone, protecting sensitive electrical components from heat damage. This design ensures the actuator operates within safe temperature limits, which enhances its reliability and extends its operational lifespan in steam lines, hot chemical processes, and heated tanks.

Reliable Operation in Submerged or Humid Conditions

Decanter valves are often used in wastewater treatment plants and industrial sumps where the valve body may be submerged or exposed to splashing. The extended shaft makes it possible to keep the actuator well above the fluid level. For fully submerged installations, the shaft can be protected by a sealed extension housing or pipe, preventing water ingress and ensuring that torque transmission remains unaffected by the environment. This approach provides consistent and safe operation even under challenging field conditions.

Durable Construction for Corrosive Media

To withstand corrosive environments found in chemical plants or effluent treatment systems, the shaft extension is typically made from high-grade stainless steel such as SS304 or SS316. This choice of material ensures long-term corrosion resistance and mechanical integrity even when exposed to aggressive chemicals, humid air, or sludge. The rugged design allows the valve to be used confidently in demanding applications with minimal maintenance.

Precision and Stability Over Long Distances

Despite the physical length of the extension shaft, the design ensures precise and stable torque transmission from the actuator to the valve disc. The extended assembly is engineered to avoid excessive flexing or misalignment, maintaining the responsiveness and reliability expected from a quarter-turn butterfly valve. This allows for accurate opening and closing control, even in large-diameter valves mounted deep inside process tanks or underground chambers.

Customizable for Site-Specific Requirements

Every installation is unique, and the extended shaft design can be customized in terms of length, mounting brackets, and actuator position to meet the exact requirements of the site. Whether the actuator needs to be installed at floor level, on a platform, or outside a hazardous zone, the extension can be fabricated accordingly. This flexibility makes these valves suitable for a wide range of process layouts, enhancing safety, serviceability, and automation integration.

Get the Perfect Fit – Custom Extensions Built for Your Application

No matter how deep the tank or how demanding the environment, we’re ready to deliver motorized butterfly valves with custom extension shafts tailored to your exact needs. From high-temperature zones to fully submerged installations, our engineering team can design and manufacture valves with any extension length, material specification, and actuator configuration to suit your plant layout.

Talk to us today and get a solution that fits your process, not the other way around.

High-Quality Material Selection

Valves are available in robust materials such as Stainless Steel (SS304/SS316), Cast Iron with Epoxy Coating, UPVC, and Ductile Iron, ensuring corrosion resistance and durability for use in water, wastewater, chemical, and high-temperature applications.

Valve Types of Ball & Butterfly

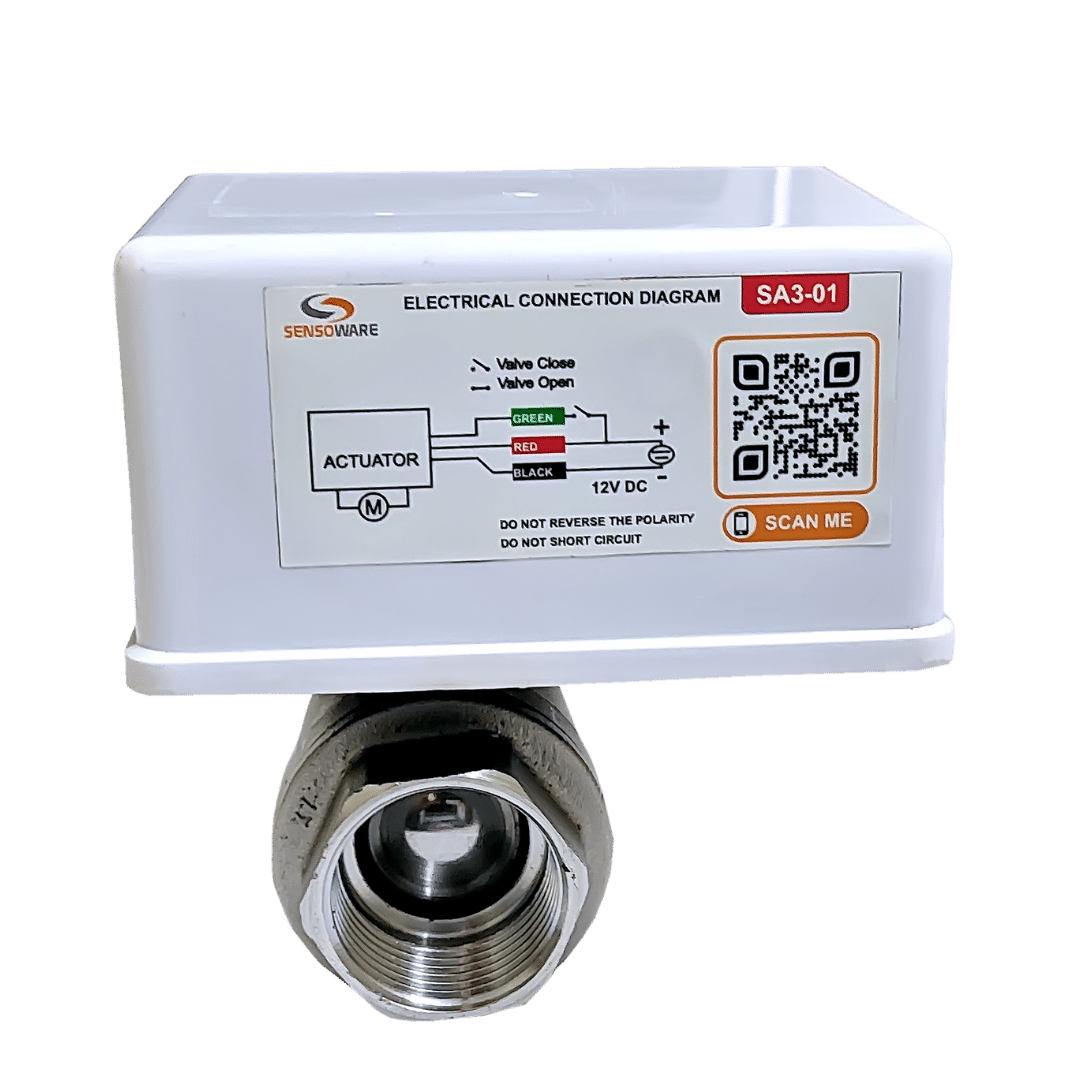

Choose from Motorized Ball Valves for tight shutoff in on/off control or Motorized Butterfly Valves for cost-effective flow regulation in larger pipelines. Both types can be configured with extended shafts or special mounting as per application needs.

Flexible Voltage Options

Actuators are available in multiple power configurations, including 12VDC, 24VDC, 24VAC, 110VAC, 230VAC, and 415VAC, offering compatibility with a wide range of industrial and automation systems.

BMS & SCADA Ready

All motorized valves can be supplied with limit switch feedback, and advanced models support Modbus RTU (RS-485) and Modbus TCP/IP protocols for seamless integration with Building Management Systems (BMS), PLCs, and SCADA platforms.

See in Action!

Browse Related Products

Follow our Social Channels